P R A N C I N G M O O S E . C O M

D A V E ' S V O L V O P A G E

| Microsquirt Conversion Harnesses Info for 240 or 740 |

|

UPDATED: September 21, 2024 CONTACT

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

https://www.youtube.com/watch?v=XZM7n9MXciQ

Questions? CONTACT ME

Update September 2024: MS harness parts are now out of stock - no longer available.

|

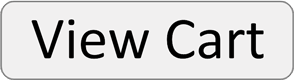

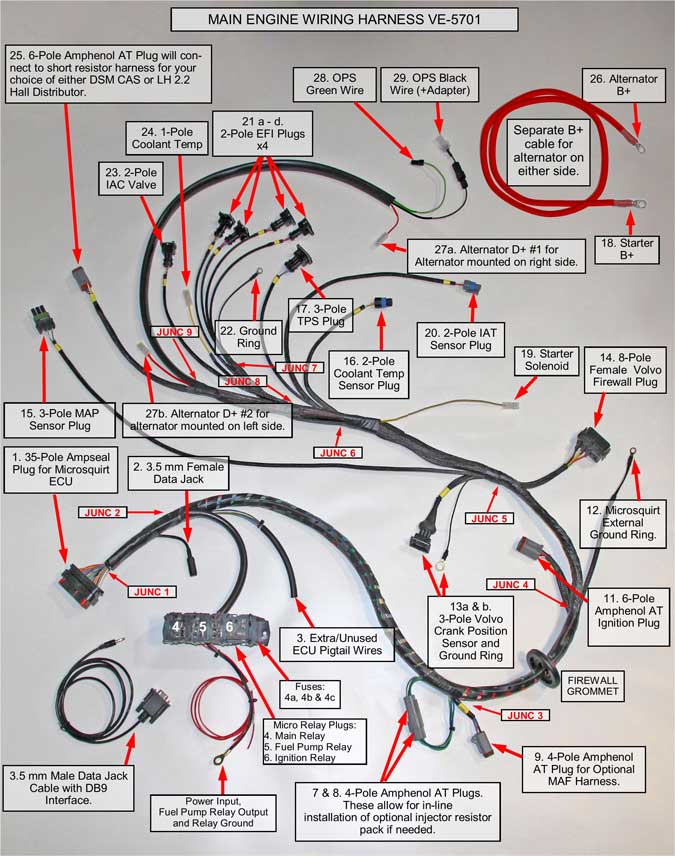

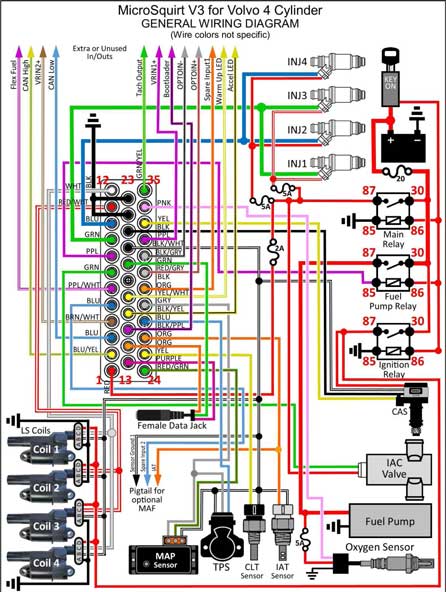

| VE5701 240 Microsquirt V3 Main Engine Harness: Completed harnesses are no longer available. Yes, these harnesses are no longer being made, however this information will remain here for anyone wishing to use it to create their own harness builds. The harness PDF assembly guide linked below has been enhanced and offers substantial detail for anyone wishing to use it for your own project. All parts, connectors and terminals are detailed with dimensions, sizes and part numbers needed to complete a harness build on your own.  CLICK IMAGE FOR LARGER ONE  FULL 240 MS HARNESS GUIDE (41 pages, 8 mb PDF) https://www.davebarton.com/pdf/Harness_Microsquirt240-2024.pdf

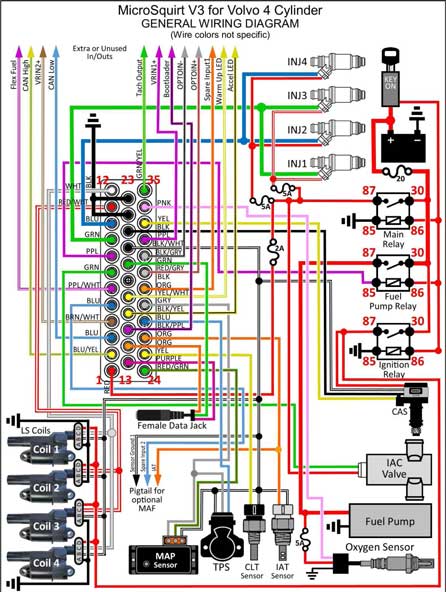

FULL DESCRIPTION Microsquirt V3 engine harness for Volvo 240 (or 740) 4 Cylinder (Microsquirt ECU not included) This main engine harness has been specifically designed for the use of Microsquirt V3 with a Volvo 4 cylinder in a 240. The 740 version harness may be found HERE.

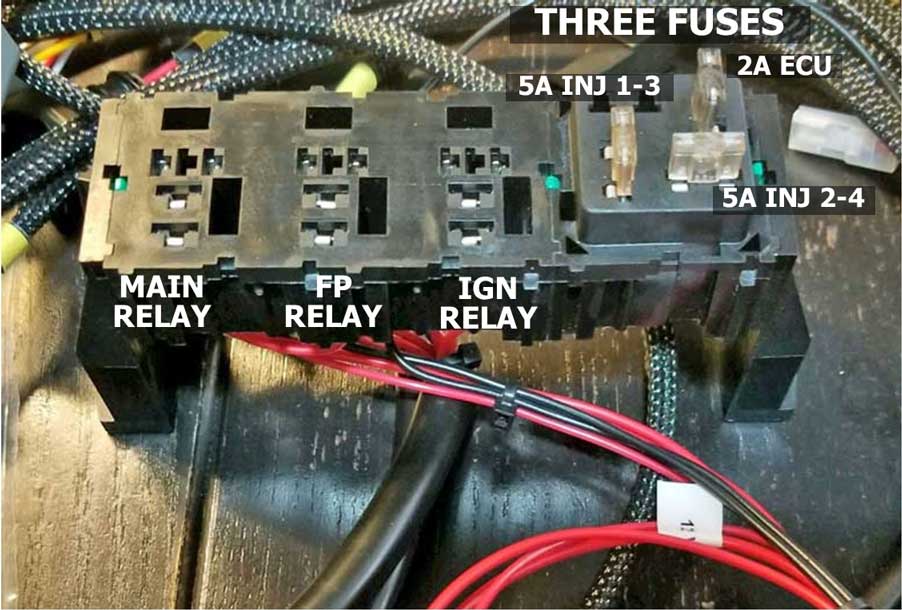

RELAY AND FUSE BLOCK  |

| SUB-HARNESSES |

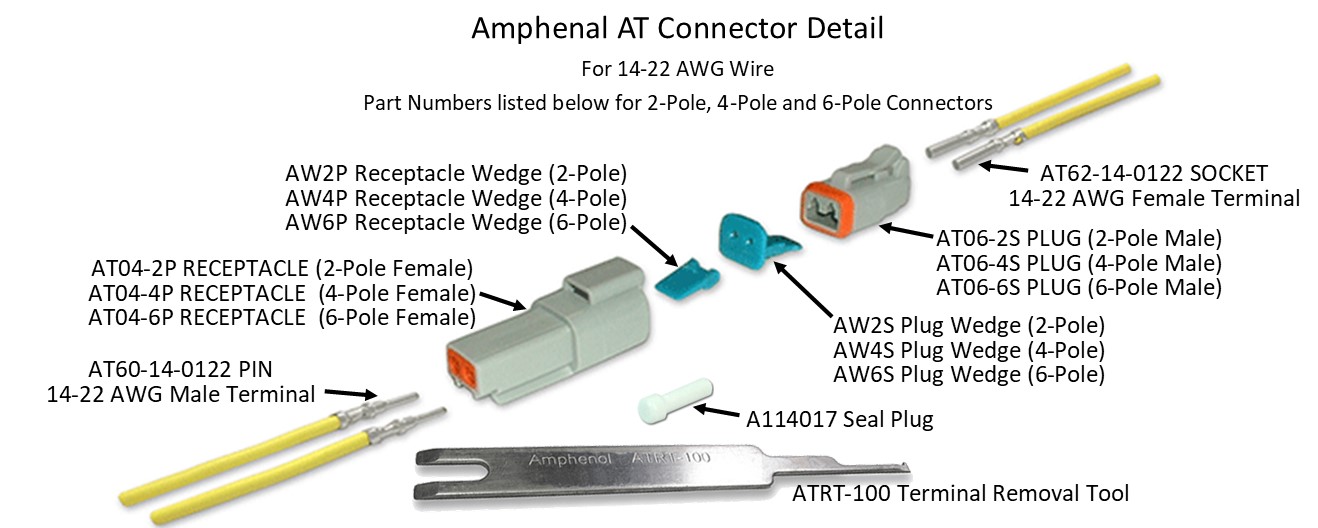

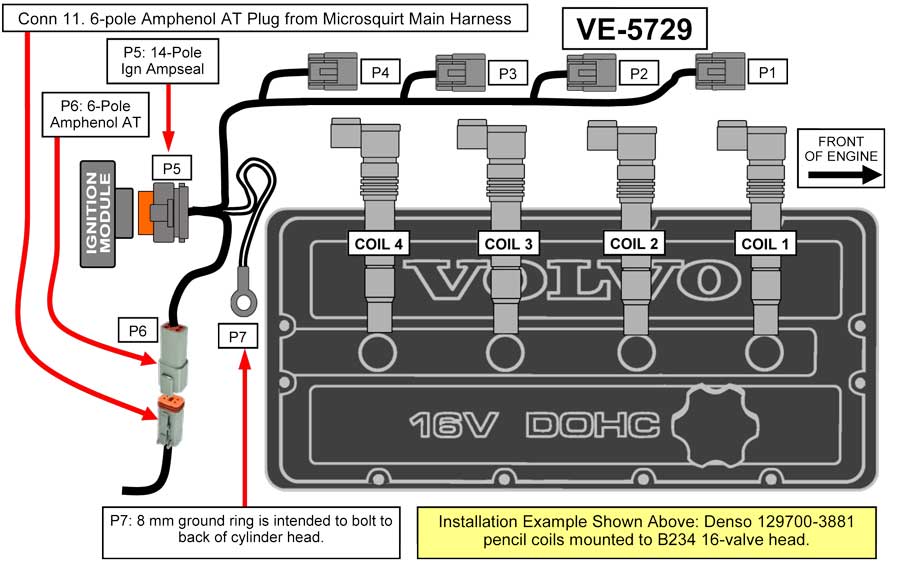

| VE5729 Coil-On-Plug (COP) Pencil Coil Harness: COMPLETED HARNESSES NO LONGER AVAILABLE Parts available at top of page. CLICK IMAGE FOR LARGER ONE  The optional COP Harness comes fully assembled and includes a 6-pole plug, which connects to the main engine harness, a 14-pole plug for the ignition module, four coil plugs and a ground ring. This harness is designed for use with Denso pencil style coils (PN 129700-3881). This sub-harness is intended for use with the YOSHIFAB FOUR-CHANNEL IGNITION MODULE, which may be mounted on the firewall. |

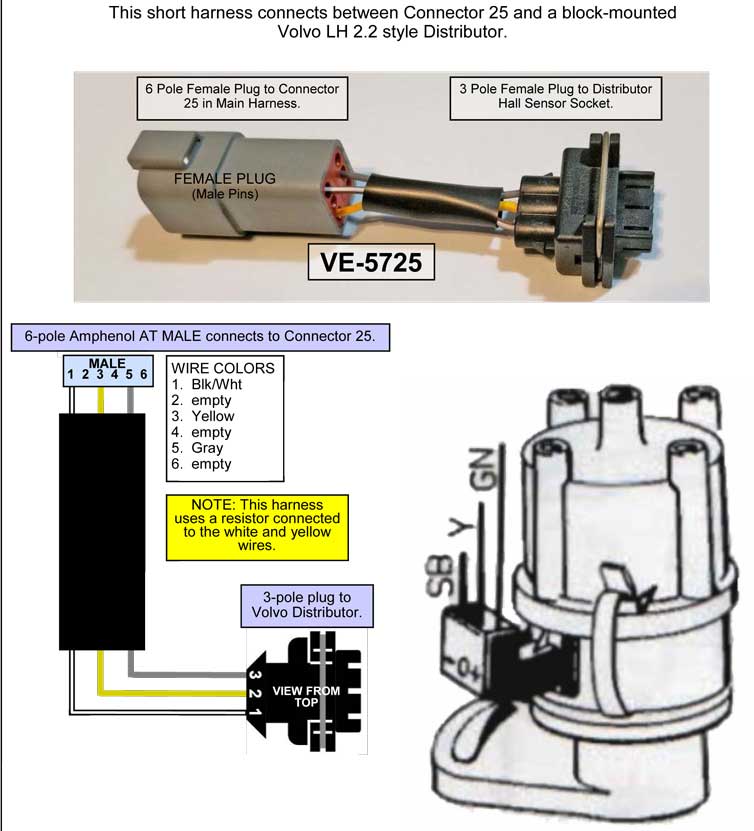

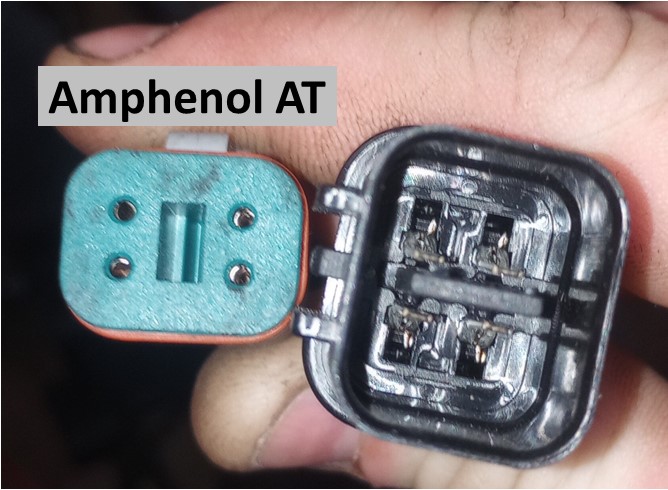

| VE5727 Short CAS Resistor Harness: COMPLETED HARNESSES NO LONGER AVAILABLE Parts available at top of page. CLICK IMAGE FOR LARGER ONE  This optional sub-harness is intended for use with the Yoshifab Cam Angle Sensor (CAS), which is available for a block-mounted (240) location or for a head-mounted 740 location. The CAS is used to provide engine speed/timing data for the Microsquirt ECU. OPTIONAL 4-POLE CONNECTOR DELETE  The Amphenol AT 4-pole connector shown above normally comes on this adapter harness and it connects to the Yoshifab CAS. The CAS as supplied by Yoshifab may come with a DIFFERENT connector shown. You may ask Yoshifab to provide the Amphenol AT connector on the CAS, or you may order this adapter harness here without the Amphenol AT 4-pole connector. In this case the harness will come with un-terminated wire pigtails and you can add the connector of your choice. |

| VE5723 MAF Sensor Pigtail Harness: COMPLETED HARNESSES NO LONGER AVAILABLE Parts available at top of page. [NO IMAGE AVAILABLE] This optional sub-harness is intended for use with an option MAF Sensor. This harness is intended to connect to Connector 9 on the main engine harness. |

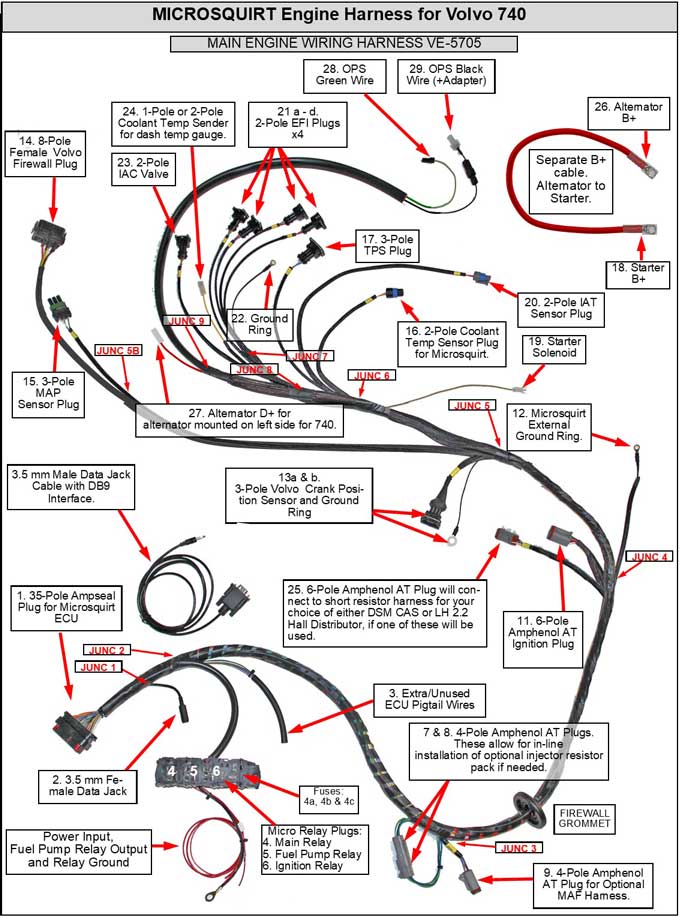

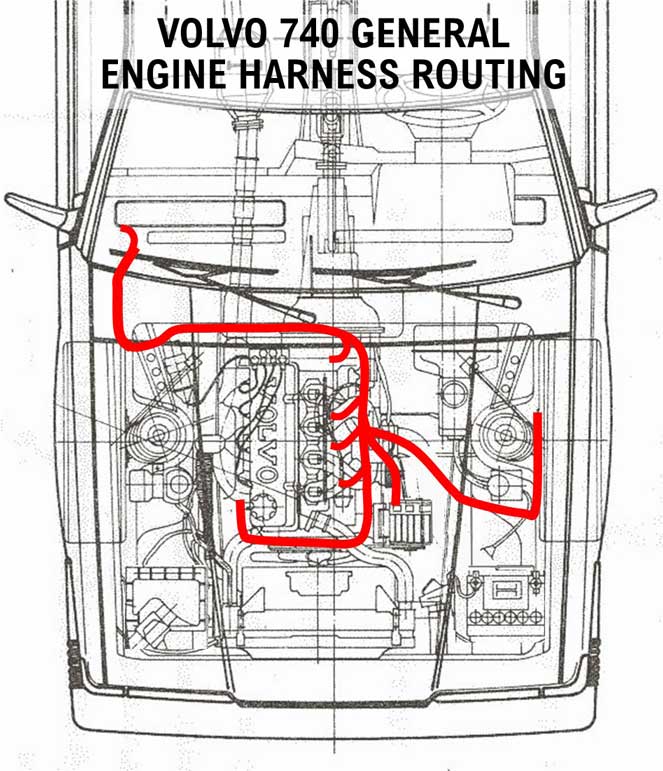

| VE5705 740 Microsquirt V3 Main Engine Harness: For full description, please CLICK HERE. COMPLETED HARNESSES NO LONGER AVAILABLE Parts available at top of page. Yes, these harnesses are no longer made, however this information will remain here for anyone wishing to use it to create their own harness builds. The harness PDF guide linked below has been enhanced and offers substantial detail for anyone wishing to use it for your own project. All parts, connectors and terminals are detailed with dimensions, sizes and part numbers needed to complete a harness build on your own.  CLICK IMAGE FOR LARGER ONE  FULL 740 MS HARNESS GUIDE (43 pages, 8 mb PDF) https://www.davebarton.com/pdf/Harness_Microsquirt740-2024.pdf

|

OTHER MICROSQUIRT RESOURCES (PDF files)

https://www.msextra.com/doc/pdf/Microsquirt_Hardware-3.3.pdf

https://www.msextra.com/doc/pdf/Microsquirt_Hardware-3.4.pdf

http://www.carquestprofessionals.com/catalogs/engine_controls/Denso-Catalog.pdf

https://www.bosch-motorsport.com/content/downloads/Raceparts/Resources/pdf/Data%20Sheet_70101387_Temperature_Sensor_NTC_M12.pdf

https://www.finjector.com/documents/51907d67c691b/0280130026.pdf

https://m.littelfuse.com/~/media/commercial-vehicle/datasheets/automotive-fuse-holders/powr-blok-modules-datasheet.pdf?la=en

https://www.whiteproducts.com/downloads/WhiteProductsCatalog.pdf (Weather Pack)

http://www.frankencis.com/portals/FrankenCIS/FrankenCISTechnical.pdf

https://www.usshift.com/downloads/tps.pdf

http://jimwolftechnology.com/wolfpdf/MAF%20Z32%20CONVERT%20TO%20OTHER%20NISSANS.PDF

https://nistune.com/docs/MAF_and_Consult_pinouts.pdf

https://www.efisource.com/wp/docs/Microsquirt-stepper-adapter.pdf

|

|